Blog

How to Choose Stainless Steel Woven Wire Mesh for Your Needs

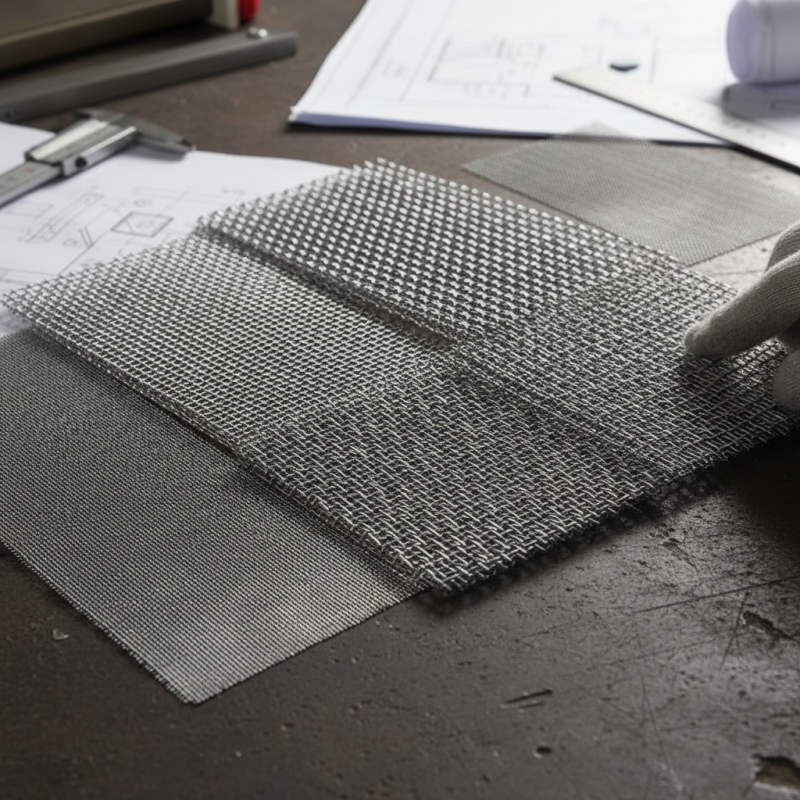

Choosing the right material for your projects can be challenging. One popular option is stainless steel woven wire mesh. This versatile material has numerous applications. From construction to filtration, it offers durability and strength.

When selecting stainless steel woven wire mesh, consider your specific needs. The mesh type, size, and weave pattern are crucial. Different projects require different specifications. A fine mesh may suit filtration, while a heavier gauge is better for structural support.

It's essential to reflect on your project goals. Sometimes, what seems ideal may not be practical. Mistakes in choosing the wrong mesh can lead to failures. Take the time to assess your requirements carefully. Effective decisions often stem from thorough contemplation.

Understanding Stainless Steel Woven Wire Mesh: Material Composition and Grades

Stainless steel woven wire mesh is valued for its strength and corrosion resistance. It is composed primarily of chromium, nickel, and varying levels of carbon. The most common grades include 304 and 316. Grade 304 is suitable for many applications due to its durability. It can withstand temperatures up to 870°C, but it is less corrosion-resistant than 316.

Grade 316 contains molybdenum, enhancing its resistance to chlorides and other corrosive elements. In coastal areas, 316 stainless steel is preferred. According to a recent market report, around 30% of stainless steel applications use 316 due to its superior properties in demanding environments.

Choosing the right grade affects performance. Some industries require specific compositions to meet regulatory standards. Inadequate material selection could lead to early failure. A thorough understanding of these grades is crucial for optimal application. Misjudging the environment might result in increased maintenance costs.

Stainless Steel Woven Wire Mesh: Material Composition and Grades

Assessing Mesh Specifications: Wire Diameter, Opening Size, and Weave Type

When selecting stainless steel woven wire mesh, it’s crucial to focus on mesh specifications. Three main factors come into play: wire diameter, opening size, and weave type. Each plays a significant role in determining the mesh’s strength and functionality. A thicker wire diameter generally provides better durability. However, it might not be necessary for all applications. Sometimes, thinner wires can adequately meet specific needs.

Opening size is just as important. Smaller openings can filter finer particles, while larger ones allow for more airflow. Think about your intended use. Do you need filtration or structural support? These questions can help narrow down your options. It’s also worth noting that sometimes a compromise might be necessary. A mesh that’s perfect on paper could be impractical for real-world usage.

Lastly, consider the weave type. Various weaves affect flexibility and strength. Twill weaves offer a balance of strength and flexibility. Plain weaves are simple but can limit application versatility. Evaluate the trade-offs. Finding the perfect mesh can require adjustments based on your expected outcomes. Reflecting on these variables can lead to better decision-making, ensuring you choose a mesh that fits your unique needs.

Evaluating Application Needs: Industrial Use vs. Decorative Purposes

When choosing stainless steel woven wire mesh, it's crucial to evaluate your application needs. For industrial use, factors like durability and corrosion resistance are paramount. The global mesh market is projected to reach $4.5 billion by 2026, driven by industrial demands. High-strength stainless steel meshes can withstand harsh environments. They resist rust and wear, ensuring longevity. However, not all stainless steel is created equal. Grades vary, affecting performance.

On the other hand, decorative purposes require a different approach. Aesthetic appeal is key in this application. For example, architectural designs now frequently incorporate woven wire mesh for visual interest. Reports suggest a 15% increase in decorative mesh applications over the last few years. It's essential to consider how the mesh interacts with light and context in a space. Yet, some designs may lack the strength needed for long-term use. Balancing beauty and functionality can be challenging. Choose carefully to avoid potential disappointments.

Key Industry Standards: ASTM and ISO Guidelines for Wire Mesh

Choosing the right stainless steel woven wire mesh requires understanding industry standards. ASTM and ISO guidelines are crucial. ASTM provides specifications on material properties and testing. These standards ensure the mesh performs under various conditions. ISO standards focus on quality management and consistency. They help in assessing the uniformity of manufacturing processes.

Tips for selecting woven wire mesh include checking for the right material grade. The grade affects corrosion resistance and strength. A higher grade may cost more, but it often provides better longevity. Pay attention to the mesh's wire diameter. It correlates directly to strength and filtration applications.

Some details matter a lot. Specifications can be overwhelming. It’s easy to overlook the importance of mesh opening size. Make sure to match the size to your application’s needs. Consider also the environmental conditions where the mesh will be used. If you find inconsistencies in samples, do not hesitate to ask the supplier for clarification. Reflect on your specific use case to avoid common mistakes.

How to Choose Stainless Steel Woven Wire Mesh for Your Needs - Key Industry Standards: ASTM and ISO Guidelines for Wire Mesh

| Mesh Type | Wire Diameter (mm) | Opening Size (mm) | Aperture (%) | Standard Compliance |

|---|---|---|---|---|

| Plain Dutch Weave | 0.5 | 0.3 | 30% | ASTM A580 |

| Reverse Dutch Weave | 0.8 | 0.5 | 22% | ISO 9044 |

| Twill Weave | 0.6 | 0.4 | 28% | ASTM E2010 |

| Leno Weave | 0.4 | 0.2 | 35% | ISO 4783 |

| Square Mesh | 0.3 | 0.3 | 40% | ASTM A240 |

Cost Considerations: Analyzing Pricing Factors and Quality Trade-offs

When analyzing the cost of stainless steel woven wire mesh, several factors come into play. Pricing varies depending on the mesh's grade, wire diameter, and weave type. According to a recent industry report, higher-grade stainless steel can increase material costs by up to 25%. Lower-grade options may save money upfront but can lead to higher long-term replacement costs due to wear or corrosion.

Understanding these trade-offs is essential. For instance, a finer mesh might be more expensive but offers better filtration. Alternatively, a coarser mesh may suffice for certain applications where particle size isn't critical. Balancing initial investment against potential utility remains crucial in decision-making.

Tips for purchasing stainless steel woven wire mesh:

- Always analyze your specific needs before making a choice. The wrong mesh type can lead to inefficiencies.

- Consider sourcing from multiple suppliers to compare prices.

- Don’t hesitate to negotiate; prices can vary significantly.

- Sometimes, it may be wise to spend a bit more for quality to avoid future issues.

- The right mesh can save money in the long run.