Blog

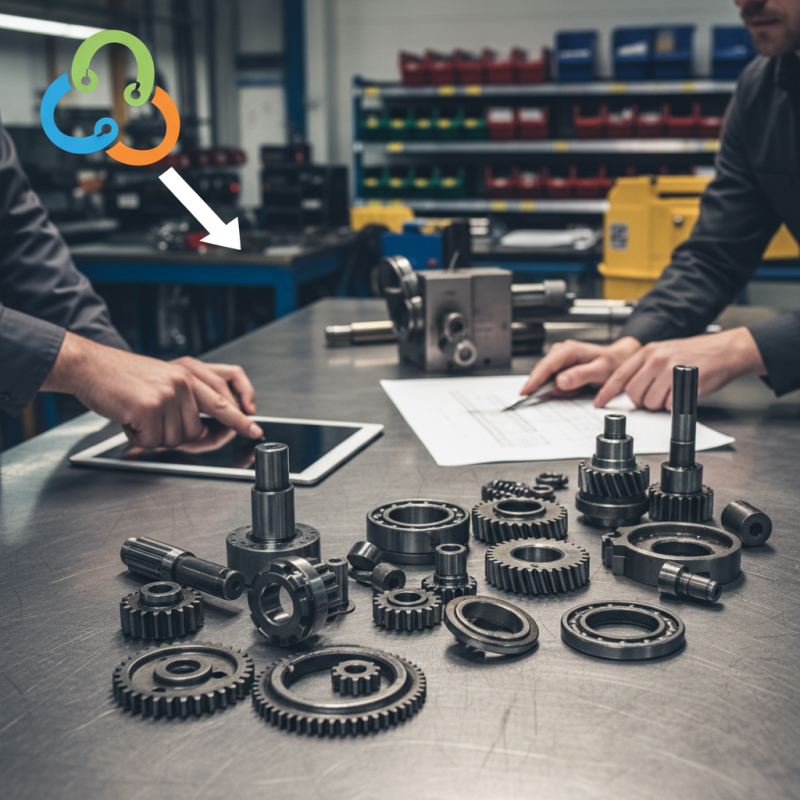

How to Choose the Best Mechanical Parts Suppliers for Your Needs?

Choosing the right mechanical parts suppliers is crucial for any project. The wrong choice can lead to delays and increased costs. Quality is important, but it’s not the only factor. Reliability, service, and communication also matter.

When evaluating suppliers, consider their experience in the industry. Look for a track record of delivering quality products on time. Review their customer service reputation. A supplier who is easy to work with can make a big difference.

It's also wise to check the range of products offered. A supplier with diverse options can save time. Be mindful of pricing too. While cost is a factor, the cheapest option might not serve your needs well. Sometimes, suppliers may overpromise and underdeliver. Ensuring that you choose wisely will pay off in the long run.

Identifying Your Mechanical Parts Requirements for Supplier Selection

When selecting the best mechanical parts suppliers, understanding your requirements is vital. Start by listing the specific components your project needs. Consider factors like dimensions, material properties, and tolerances. This will help you narrow down potential suppliers. If your project requires custom parts, clarity on specifications becomes even more critical.

Communicating your needs effectively can sometimes be challenging. Misunderstandings may occur if details are vague. Engage in discussions with suppliers to clarify expectations. This dialogue could reveal issues such as lead times or pricing structures. Addressing these points early can prevent delays down the line.

Remember, not all suppliers will fit your specific needs. Some may excel in quality but struggle with timely delivery. Others might offer cost-effective solutions but lack adequate support. Reflect on the trade-offs between quality, price, and reliability. This approach will guide you toward the right choice for your mechanical parts needs.

Researching Potential Mechanical Parts Suppliers in Your Area

When researching potential mechanical parts suppliers, location plays a crucial role. Proximity can reduce shipping times and costs. According to industry reports, local suppliers often provide better customer service and quicker turnaround times. This is key for businesses with tight production schedules.

Tip: Prioritize suppliers within a reasonable distance. This can enhance communication and expedite delivery. Look for those with established reputations in your region. Online reviews and testimonials can offer insights into reliability.

While finding suppliers, consider their specialization. Some suppliers excel in specific parts or industries. Understanding their expertise can prevent misalignments. A report indicated that 45% of businesses faced issues due to mismatched capabilities. Visit potential suppliers and assess their operations.

Tip: Engage in conversations. Ask about their manufacturing processes and quality control measures. This can reveal potential shortcomings. A hands-on approach is essential for evaluating their compatibility with your needs.

Evaluating Supplier Credentials and Industry Experience

When selecting a mechanical parts supplier, evaluating their credentials is crucial. Look for suppliers with a solid track record. They should have relevant industry experience, showcasing years of service. This can indicate reliability and capability. Consider their certifications as well. These credentials add to their credibility.

Tips: Check customer reviews and testimonials. These offer insights into the supplier's reliability. A diverse portfolio may indicate versatility, but it can also raise questions about their focus. Have they specialized in one area? Specialization can mean deeper expertise, but it might limit their adaptability.

Industry experience is not just about time. It involves understanding market trends and technological advancements. Suppliers should be engaged in continuous improvement. Ask them how they keep up with industry changes. Additionally, consider their responsiveness to inquiries. Delayed responses may highlight potential issues in their operations. Choose wisely. Your projects may depend on it.

Comparing Pricing Structures and Quality Assurance Practices

When selecting mechanical parts suppliers, pricing structures play a crucial role. It's essential to analyze how suppliers determine their costs. Some may use fixed pricing, while others operate on a cost-plus model. Understanding these methods helps in comparing offers. A transparent supplier usually outlines potential additional costs. This reflects on their reliability. If the pricing seems too good to be true, it often is. Lower costs may hint at compromised quality or hidden fees.

Quality assurance practices are equally significant. A supplier’s commitment to quality can be observed through their testing protocols. Some may perform regular tests, while others might skip these crucial steps. Look for certifications that indicate high standards. Suppliers who prioritize quality often have higher prices, but this investment pays off in the long run. It's worth questioning the adequacy of the supplier's quality measures.

Finding the right balance between price and quality assurance can be challenging. Make a spreadsheet, compare key factors, and ask direct questions. This approach leads to more informed choices. If doubts arise, trust your instincts. After all, a poor decision in supplier selection can lead to costly and time-consuming consequences down the line.

How to Choose the Best Mechanical Parts Suppliers for Your Needs? - Comparing Pricing Structures and Quality Assurance Practices

| Supplier Type | Pricing Structure | Quality Assurance Practices | Lead Time | Customer Support |

|---|---|---|---|---|

| Local Manufacturer | Fixed Rates | ISO 9001 Certified | 3-5 Days | Email & Phone Support |

| International Supplier | Variable Costs | Six Sigma Practices | 2-3 Weeks | 24/7 Online Support |

| Online Marketplace | Auction & Bidding | Vendor Ratings System | Variable | User Forums |

| Specialized Distributor | Tiered Pricing | Regular Audits | 1 Week | Dedicated Account Manager |

Assessing Customer Support and After-Sales Services

When choosing mechanical parts suppliers, customer support plays a crucial role. Strong support can save you time and money. A supplier's responsiveness to inquiries is important. You want a partner who values your time. Quick replies show commitment. If a supplier takes days to respond, reconsider your options.

After-sales service is equally significant. Imagine receiving damaged parts or encountering installation issues. A supplier should offer clear steps for addressing problems. Some suppliers provide comprehensive guides, while others may leave you hanging. Check if they have a dedicated support team. This can make a big difference when you face challenges.

Attending to feedback can indicate a supplier's reliability. Ask for references or read reviews. Look for comments on their after-sales support. This will give insight into their reliability. Be wary of overly positive reviews. They might not paint the complete picture. A good supplier should demonstrate a willingness to learn and improve.